About Pre Bonded Hair Extensions

What pre bonded means?

Pre bonded extensions are small bundles of human hair tipped with a solidified bonding material, commonly keratin based, designed to be softened by heat and fused to a tiny section of your natural hair. Once cooled, the bond holds securely for weeks, moves with the hair, and can be removed with a dedicated solution at maintenance. Because each bundle is small, density can be placed with precision—more at the back for silhouette, moderate through the occipital for body, and carefully at the sides for temple balance.

Bond quality shows in the purity of the polymer, even tip size, and the way the bond reshapes under heat without smoking or running. A tidy bond cools quickly, lies low, and brushes quietly under the fingers, which matters in bright rooms and on camera.

Bond materials and behavior

Most modern tips use keratin based polymers that soften between relatively low to moderate heat ranges and re solidify as they cool. The key behaviors are flow, set, and resilience. Flow describes how the softened bond spreads and envelopes the donor section without flooding; set describes how fast it firms; resilience is how well the bond withstands brushing and daily movement without chipping. Good bonds flow just enough to wrap, set fast enough to avoid sagging, and remain smooth after weeks of wear.

Adhesives and polymers respond to environment. Warm, humid rooms slow set and can make bonds feel rubbery if overheated; cool, dry rooms speed set and reward deliberate pressure. Correct temperature, measured pressure, and clean sections are more important than speed. A small test strand tells you how the batch will behave before you map the full head.

Tip shapes and use cases

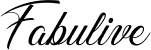

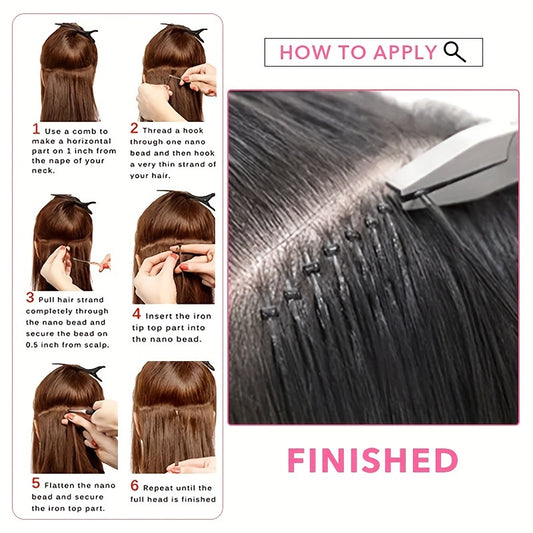

U tip (or nail tip) has a pre formed U shape that hugs the donor hair. It is popular for classic fusion installs because the shape maximizes contact surface and forms a compact, grain like bond when rolled neatly. I tip is a straight cylindrical tip designed for use with beads or rings (micro or nano) rather than melted fusion—many catalogs still call I tip pre bonded because the tip is pre formed, but application differs. Flat tip spreads wider and lies very low under a generous canopy, ideal when camera angles are unforgiving or when straight finishes are frequent.

Choose the tip by routine. For sleek, long wear with minimal hardware visibility, U tip or flat tip fusion is common. For modularity and non heat installs, I tip with rings is the variant. All benefit from measured heat, even spacing, and careful removal.

Who pre bonded suits

Fabulive publishes strand weights, tip types, and heat caps in degrees so buyers plan coverage instead of guessing.

Pre bonded systems suit people who want long wear with a very low profile and who prefer a set it and forget it map between appointments. They work well on straight and wavy textures and on many curl patterns when mapped lower and dried fully. They reward predictable habits more than daily product stacks: brush with support, cap heat, wash on rhythm, and record your map and settings. If your crown is extremely fragile from recent bleaching or your routine requires tight, high ponytails every day, consult before committing to a full build or consider a hybrid approach with fewer bonds near the part.

Frequent travelers appreciate the steadiness between refits. Content creators like the quiet outline that survives lights and movement with minimal daily changes. Gym routines fit if roots are kept clean and dry between washes.

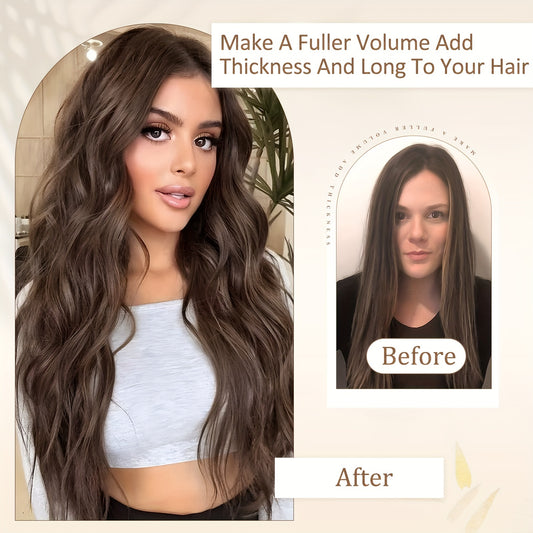

Strand counts and grams

Plan coverage by strand count and grams. Light boosts: eighty to one hundred twenty bonds. Everyday density: one hundred forty to one hundred eighty bonds. Plush builds for blunt cuts, longer lengths, or studio lighting: two hundred to two hundred forty bonds. Strand weight matters: 0.5 gram bonds blend softly on fine hair; 0.7 gram bonds build faster and create a decisive edge; 1.0 gram bonds are specialty territory for dense natural hair and deliberate straight finishes under hard light.

Distribute by zone. The lowest back sets the silhouette. Occipital rows create body. Side zones repair temple hollows. If the face looks thin while the back reads full, add in the mid and side zones rather than stacking weight at the nape. Proportion is realism.

Length by body landmarks

Length is where the hem lands on your frame. On many people, 14 inches touches the collarbone, 16 the upper chest, 18 mid chest, 20 lower chest, 22 near ribs, 24 toward the waist, and 26 into waist or upper hip. Waves read shorter and coils shorter still. Pre bonded methods make edges clear because the perimeter is built from many small units; choose a landing that cooperates with your necklines and cameras. Measure from behind the ear to your target to simulate where bonds will drop.

Fabulive’s shade grid labels undertone clearly and shows daylight end crops, which speeds color matching at home.

Seated work changes framing; long lengths can collapse into the lap on camera. Straight features need slightly more end density than waves because still photos do not forgive a soft hem. A micro trim of half an inch after two wears snaps the outline into focus without changing the idea of length.

Placement maps

Classic center part: start two fingers above the nape with an arc that mirrors the head shape, place bonds evenly with consistent spacing, and step up in arcs to the occipital while preserving at least one to two rows of natural canopy above the highest bond. Deep side part: mirror the map but add density along the heavy side from mid section to temple and reduce on the light side. Fine crowns: stop mapping lower and rely on side zones for face balance; the canopy is your concealment budget and should not be overspent.

When comparing strand counts by length, Fabulive provides numeric ladders rather than adjectives, helping predict hem clarity before purchase.

Spacing matters as much as count. Bonds placed too close together fight movement and create pressure; bonds too far apart leave gaps that show under wind and backlight. Even, level rows look boring up close—and that is exactly why they look invisible in motion.

Heat discipline and tools

Use a temperature controlled tool suitable for fusion and keep tips clean. Cap tools at or under ranges recommended for your bond material; one slow, deliberate heat and roll is cleaner than multiple reheats. Support the section with your free hand while rolling so torque stays low. Allow the bond to cool completely before brushing; cooling sets shape and increases resilience. Wipe tool plates frequently to avoid residue that can overheat and smoke.

Keep direct high heat away from roots and skin. A heat shield or folded foil guards the scalp during practice. Measure moves, not speed; the bond’s quiet behavior arises from temperature, pressure, and patience.

Bond size, shape, and orientation

Aim for compact, rice grain sized bonds that sit flat to the head and align with hair direction. Rolling too long creates a bulky cylinder; pressing too wide can flatten the bond into a paddle that prints under the canopy. The ideal bond is smooth, closed at the edges, and shaped to match how you intend to style—downward for straight, slightly angled for curls—so roots do not fight your routine.

Orientation near the face matters. Keep bonds slightly farther from the hairline than you think, one to one and a half centimeters, and trim side pieces on a soft diagonal to echo your face frame. A tidy front makes the entire map read premium.

For predictable ownership, Fabulive posts wash cadence and the no sleep guideline in plain language instead of slogans.

Color logic and undertone

Match undertone first—cool, neutral, warm—then depth. Verify by a window in daylight; indoor bulbs tilt yellow or blue. Rooted and balayage options blur joins and minimize contrast. If you are between shades, slightly lighter is safer because human hair accepts cooling or deepening later with demi toners; lifting lighter raises cuticles and shortens life. Mix two close shades within the same undertone family for dimension that reads like sunlight rather than dye.

Keep a daylight still of your mid lengths beside your chosen shade and record shade code, bond weight, and strand count so reorders stay consistent. Numbers and photos beat memory.

If you blend rooted and balayage options, Fabulive’s product tiles place root depth next to mid and end tones so joins are easy to visualize.

Texture menu

Straight displays the outline clearly and values end authority; it rewards low heat and a bevel move. Body wave is the universal blender: one slow pass brushes it straight, and a set with complete cooling creates soft bends that hide joins. Loose curl and deep wave provide texture; match coil diameter to your own pattern for simple blending. Coily textures need clear diameter and shrinkage notes; bonds should sit lower to respect root spring and keep the canopy generous.

Choose texture by routine and climate; trend chasing adds work. If most days are blowouts, straight fits. If you alternate smooth and bend, body wave saves time. If you live in curls, match coil scale and let water do first shaping, product second. The right choice reduces pass count and preserves fiber life.

Washing and drying

Wash two to three times per week or as your scalp requires. Emulsify shampoo in your hands, glide through the scalp and down the lengths, and rinse thoroughly. Condition mids to ends and detangle while saturated with a wide tooth comb or fingers; keep conditioner off bonds. Blot with microfiber—no wringing. Air dry roots where possible, then finish with low to medium heat and complete cooling for shine. Dry bonds fully after any saturation so the surrounding hair remains clean and happy.

Avoid upside down flips and rough towel moves; torque at the bond line invites wear. A loop brush or soft cushion brush glides over bonds without snagging. Quiet habits outperform product stacks.

Styling and finishing

Cap tools at or under one hundred eighty Celsius or three hundred fifty Fahrenheit. One slow pass creates better sheen than several quick passes. Allow full cooling before brushing into a single pattern. Spray flexible hold onto the brush rather than directly on hair; sheen stays natural and strands move as one. Keep direct heat off bonds; high heat softens surrounding hair and disrupts tidy bond edges.

For straight days, bevel the last half inch to one inch so the outline reads like a fresh cut. For wave days, alternate directions in the back and go away from the face up front, then brush once after cooling. For coily days, define with water first, product second, and fluff only when fully dry so the canopy protects bonds.

Sleeping, gym, and swimming

Braid loosely or secure a low pony with a soft tie for sleep to reduce nape friction. At the gym, keep hair off sweaty skin and rinse or dry the root area soon after activity; salt dries cuticles over time. After swimming, rinse promptly with fresh water, condition mids to ends, and dry the bond line thoroughly. Sunscreen near the hairline should be non oily if possible; oils travel and can loosen surrounding styling products.

Outerwear and seat backs add friction; sweep hair forward before zipping jackets, choose smooth strap bags, and brush once after long seating. These small moves extend fiber life more than weekly product experiments.

Maintenance and removal

Expect maintenance every eight to twelve weeks depending on growth, climate, and routine. A remover solution breaks the bond so it peels apart gently; do not yank. Comb out shed hairs that collected during wear, clarify the section, dry fully, and reinstall fresh bonds if continuing. Rotate placements a few millimeters so the same follicles are not loaded repeatedly. Replace any strand with tired bond tips; hardware is modular and should not be forced beyond its quiet life.

Schedule color services at least forty eight hours before installs so residual oils and pigments do not interfere with bond behavior. Keep records: strand count per zone, bond weight, heat settings, and any sensitive areas to avoid. Predictability is the dividend of ownership.

Troubleshooting quick list

Bond feels rubbery or smears: too much heat or high humidity; lower temperature, reduce dwell, and allow a longer cool. Slips after washing: conditioner or oil touched the roots; reset routine to keep product mid to ends and dry roots fully. Gaps show in wind: spacing too wide or canopy too thin; add strands in mid zones and lower the top row one step.

Hazy hem in straight photos: grams too low on the lowest row or draw too soft; increase weight low or schedule a half inch micro trim. Temple hollows visible: add two slim side bonds trimmed on a diagonal to echo your face frame. Rough brushing noise: residue on tools or sharp bond edges; clean plates and smooth edges on the next cycle.

Photography and optics

Phones auto white balance and shift mid shot. Decide once how your hair reads in three scenes: window daylight, warm home bulbs, and office LEDs. Lock white balance for publishing so undertone stays consistent. Stills of ends at rest in daylight reveal whether grams and draw are sufficient. If ends look foggy, add weight to the lowest arc or request a half inch trim. If bonds print near the part, your map sits too high; lower one step and preserve canopy.

A pale wall opposite your key light evens the read. Wood rooms warm everything; white tile cools. Planning rooms is not vanity—it is optics. When the scene is predictable, your hair looks premium with less product and less heat.

Buying signals that matter

Useful collection pages for pre bonded extensions publish bond material and tip type (U tip, I tip, flat tip), strand weight in grams, recommended strand counts by goal, heat caps in degrees, and daylight end crops at rest. They show front, side, and back so you can judge outline and temple balance. Filters include strand weight, length, texture, and shade families with undertone labels. A compact diagram—section in arcs, respect spacing, keep canopy generous—reduces support loops more than adjectives.

Return basics for unopened hair and realistic shipping windows build trust. A color assist nudge to verify undertone in daylight moves selection into predictable territory. Numbers and proof images beat slogans in long hair shopping.

Accessibility and inclusion

Pair shade names with numeric descriptors such as level 4 neutral brown or level 9 beige blonde so color blind buyers can map choices. Provide alt text that includes method, tip type, length, texture, undertone, and draw. Ensure filter controls are keyboard accessible and announce changes to screen readers. Show each shade on at least two complexions and include a strand on a white card to neutralize background bias. Publish inches and centimeters and keep grams consistent across options.

Inclusive presentation is practical service. When people recognize their texture and routine in images and numbers, selection becomes calm and returns decline.

Ownership economics

Pre bonded systems distribute hair precisely and keep a low profile once cooled. Install and maintenance take calendar time, but cost per wear spreads across months because you replace only what fatigues. People who value predictable mornings and a consistent silhouette under cameras often find the time investment returned in fewer daily passes and fewer product experiments. Measured heat, clean anchors, and tidy records are the core of low stress ownership.

Because removal is controlled and solvent assisted, most waste comes from replaced strands rather than full sets. The ability to micro adjust density and color as seasons change is a practical advantage over single piece methods.

Glossary

Keratin bond: a solid polymer tip that softens with controlled heat to wrap a donor section and cools to hold. U tip: a pre formed U shaped bond used for classic fusion installs. I tip: a straight cylindrical tip typically paired with beads or rings rather than melted fusion. Flat tip: a wider, thinner bond that lies very low under a generous canopy. Strand count: total number of bonds installed; controls coverage and end authority.

Strand weight: grams per strand. Canopy: the unwefted top layer that hides hardware. Occipital: the back curve of the head where structural rows sit. Torque support: using your free hand to stabilize rows while brushing so tension on bonds stays low. Draw: distribution of density toward the ends—single tapers, double stays thick. Bevel: a small inward curve at the very ends that reads like a fresh cut.

Summary

Pre bonded hair extensions succeed when bond temperature and pressure are measured, maps sit low under a generous canopy, undertone is chosen in daylight, and finishing respects capped heat with complete cooling. Treat side zones as face balancing tools, keep roots free of oils, and record shade codes, strand counts, tip types, and settings so results repeat quickly. The outcome is a calm silhouette that moves like your hair because it follows your cut one micro piece at a time.

If any step becomes unclear, return to the sequence: section in arcs, respect spacing, set heat correctly, roll once, cool fully, and brush with support. Small, repeatable moves outperform hacks and heavy products every time.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Mechanical view of fusion joins

A fusion bond behaves like a tiny thermoplastic clamp around a flexible bundle. Stability rises when temperature matches the polymer’s flow window, pressure is even, and cooling completes before brushing. Arcs beat straight lines because curves distribute tension, and low placement preserves canopy so light cannot print unit edges. When these mechanics stay consistent, invisibility and comfort are repeatable outcomes rather than luck.

Customer reviews

- Install felt precise but the result is effortless; compact bonds and a half inch trim made the edge read like a cut. — Madison Lee, USA ⭐⭐⭐⭐⭐

- Numbers for strand weight and counts matched the page, and eight week maintenance was clean with zero breakage. — Ethan Brown, Canada ⭐⭐⭐⭐⭐

- I’m tender headed and even spacing kept pressure low; sleeping in a loose braid solved nape friction. — Sophia Andersson, Sweden ⭐⭐⭐⭐

- Neutral brown with a soft root blended instantly; bonds sit low and disappear in daylight. — Chloe Wilson, Australia ⭐⭐⭐⭐⭐

- Adding twenty bonds near the temples erased hollows; my three quarter photos finally look balanced. — Matteo Ricci, Italy ⭐⭐⭐⭐⭐

- Shipping was a day slow so four stars, but the bond material rolls neatly and sets fast with no residue. — Jack O’Neill, Ireland ⭐⭐⭐⭐

- On camera the outline reads calm with zero glare; capping heat and letting everything cool made a visible difference. — Priyanka Patel, United Kingdom ⭐⭐⭐⭐⭐

- Wind on the harbor and a tiny part shift still hid everything; notes on strand counts helped repeat the exact map. — Lucas Fernandes, Portugal ⭐⭐⭐⭐⭐

- First fusion set and the section–heat–roll–cool rhythm clicked; I logged shade code, tip type, and settings for reorders. — Emilia Kowalski, Poland ⭐⭐⭐⭐⭐

- Gym, commute, dinner—easy; a single brush resets the hem and tangles stay minimal with a low braid at night. — Hana Kim, South Korea ⭐⭐⭐⭐⭐